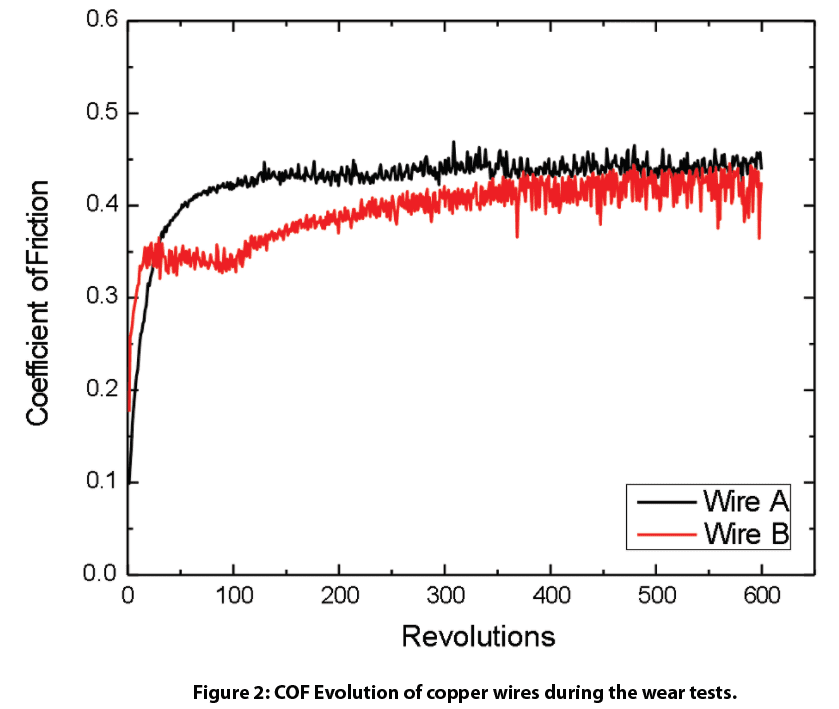

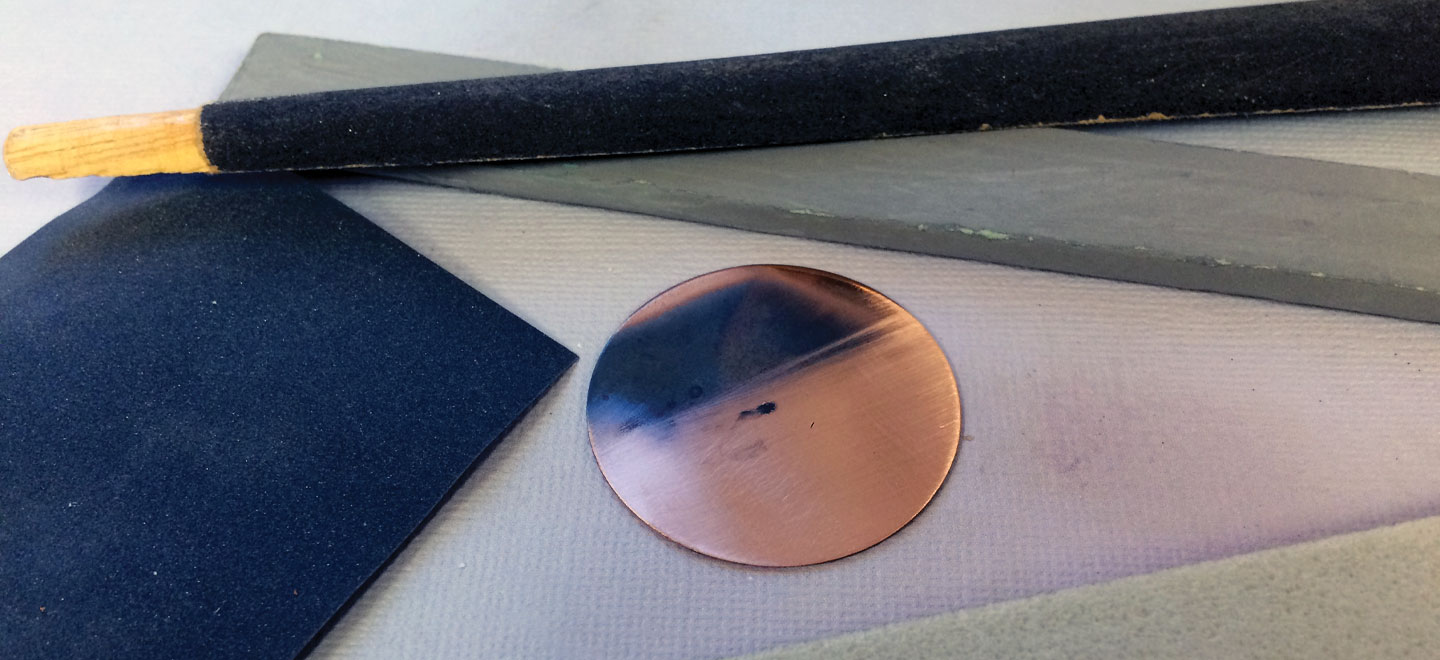

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

The Role of Submerged Arc Welding in Heavy Fabrication - Red-D-Arc Red-D-Arc

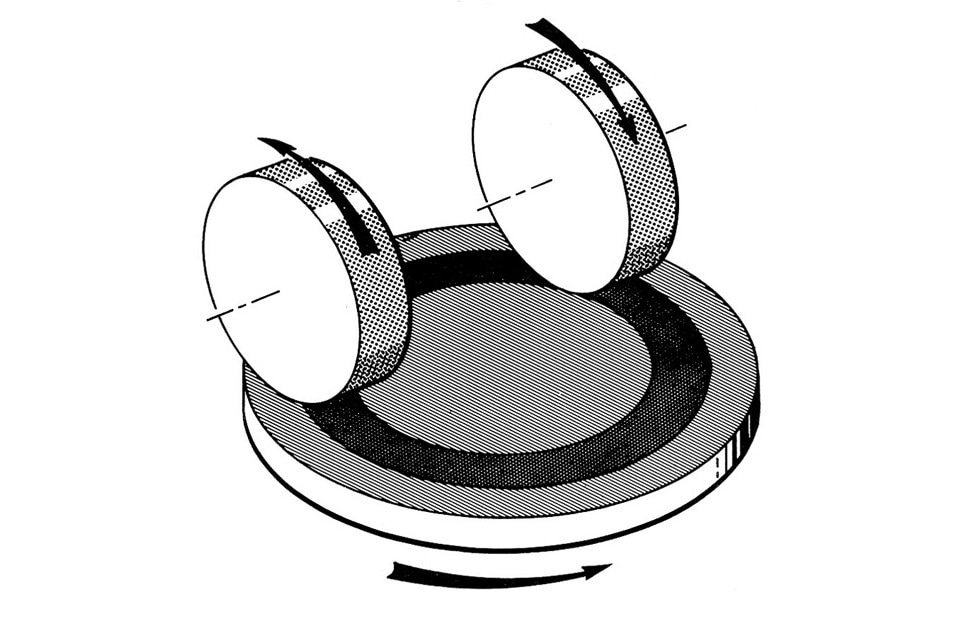

Understanding the Different Types of Abrasion Testing - The TABER Test

Guide to Jewelry Finishing Sandpapers - Halstead

Polyimide Film Wrapped Insulated Aluminum/Copper Round Wire - China Flat Wire Covered Polyimide/Polyester Film, Covered with Polyimide/Polyester Film Wire

3D Printer Nozzle Wear: Discover the mechanisms behind nozzle abrasion

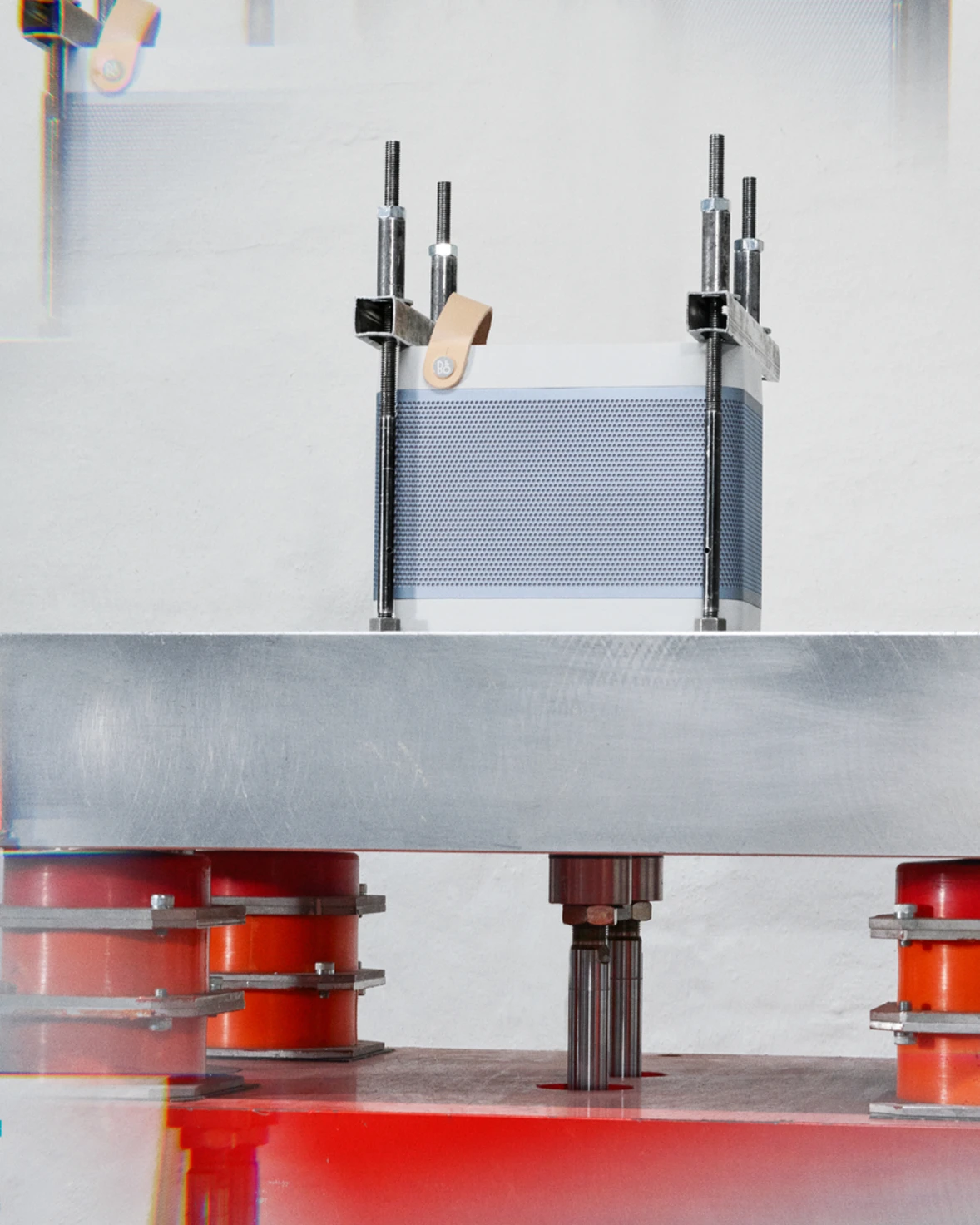

testing-the-limit

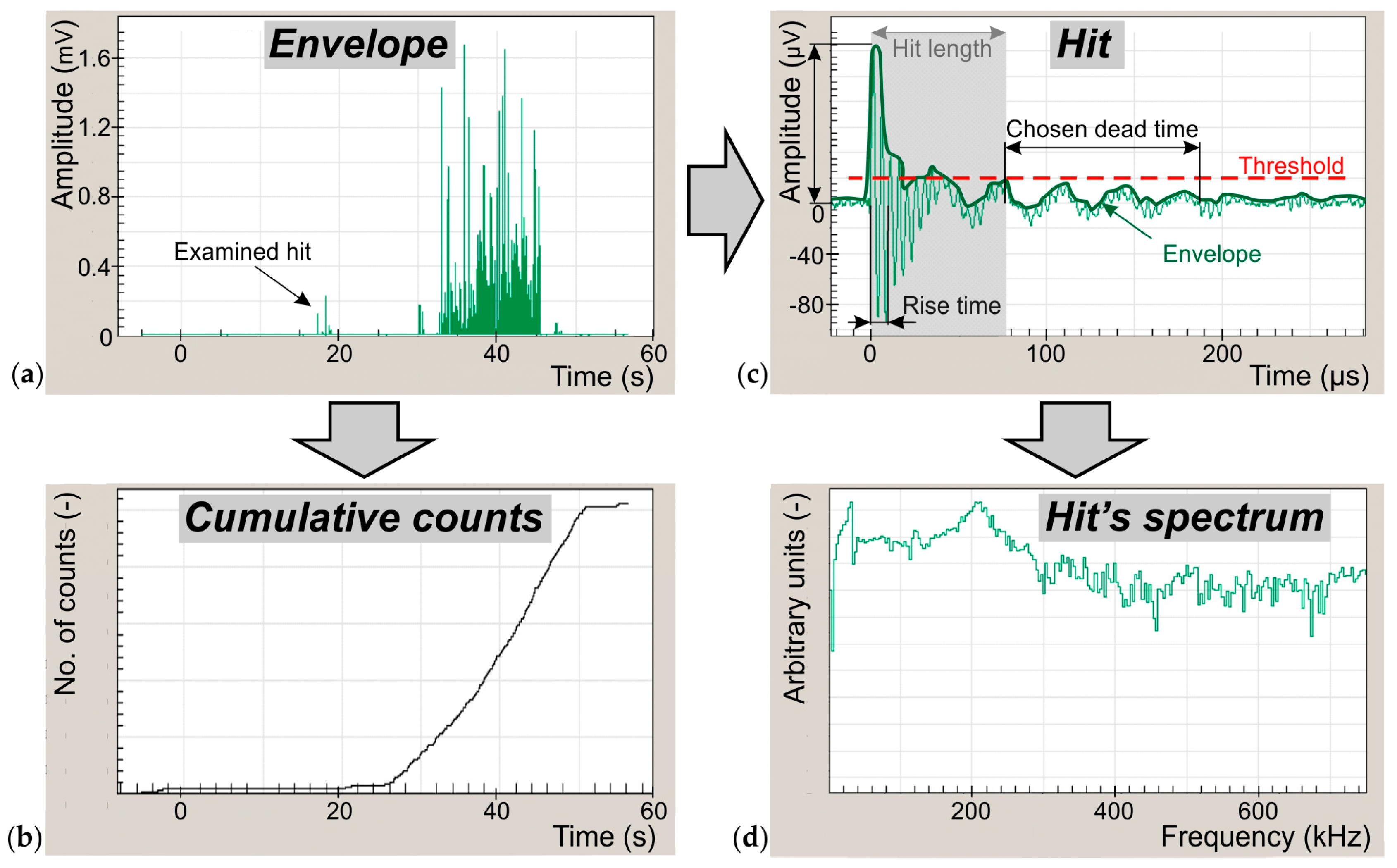

Coatings, Free Full-Text

Fine-tuning effect of Direct Laser Interference Patterning on the surface states and the corrosion behavior of a biomedical additively manufactured beta Ti alloy - ScienceDirect

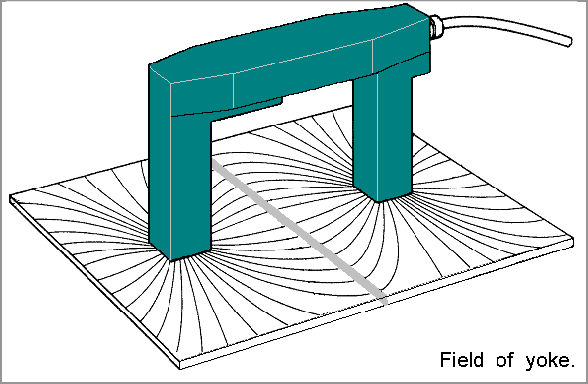

Introduction to Magnetic Particle Testing - NDT Inspect - NDT Career and Community Portal

The Material of Wire Wheel Cup Brush: Made of carbon steel material. Designed with reasonable crimped wire curvature and increased bristle thickness

6 Pcs Wire Wheel Cup Brush Set,1/4In Round Shank Wire Brush for Drill Attachment, for Cleaning Rust, Stripping and Abrasive